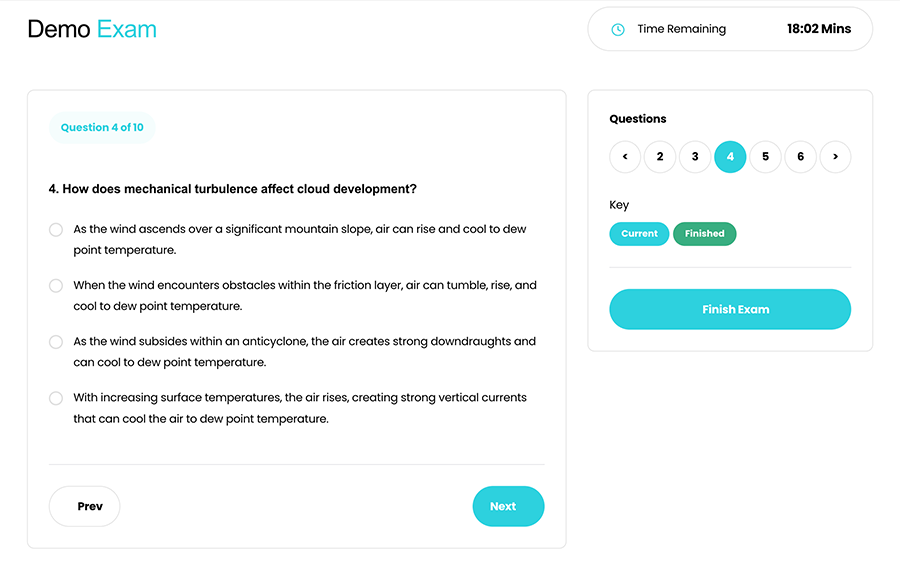

Aviation Students Test Their Knowledge With Mock Exams

Providing comprehensive online aviation mock exams under realistic conditions to test your knowledge.

Mock Exams with Unlimited Access & Realistic Results

- Unlimited Access To All Exams

- Authentic Exam Conditions with Timers

- Detailed Results & KDR Reports

- Smarter, Targeted Learning

Trusted by Pilot Students Nationwide

Trusted by Pilot Students Nationwide

How it Works

Create Your Account

Buy a Subscription

Select either a monthly or six-month subscription. Both plans grant you unlimited access to all 30 versions of the PPL/CPL mock exams (covering 1000+ questions) throughout the subscription period.

Start Your Mock Exam

Once your subscription is active, you can begin any of the available mock exams. Each exam simulates real ASPEQ test conditions, so there’s no pause button, helping you get used to the pressure.

Get Instant Results

Once you finish your exam, the system automatically generates your results. For each passed exam, you'll see which questions you answered incorrectly, along with the correct answers and related syllabus items.

What Customers Say

Available Mock Exams

Get unlimited access to over 1000 questions across PPL/CPL subjects with a subscription, no more one-time vouchers! Test yourself as many times as needed, with 30 mock exam versions and regular updates to keep your learning fresh.

125 Questions

125 Questions

Flight Radiotelephony

Private Pilot Licence (PPL)

225 Questions

225 Questions

Meteorology

Private Pilot Licence (PPL)

Commercial Pilot Licence (CPL)

170 Questions

170 Questions

Air Navigation and Flight Planning

Private Pilot Licence (PPL)

Commercial Pilot Licence (CPL)

270 Questions

270 Questions

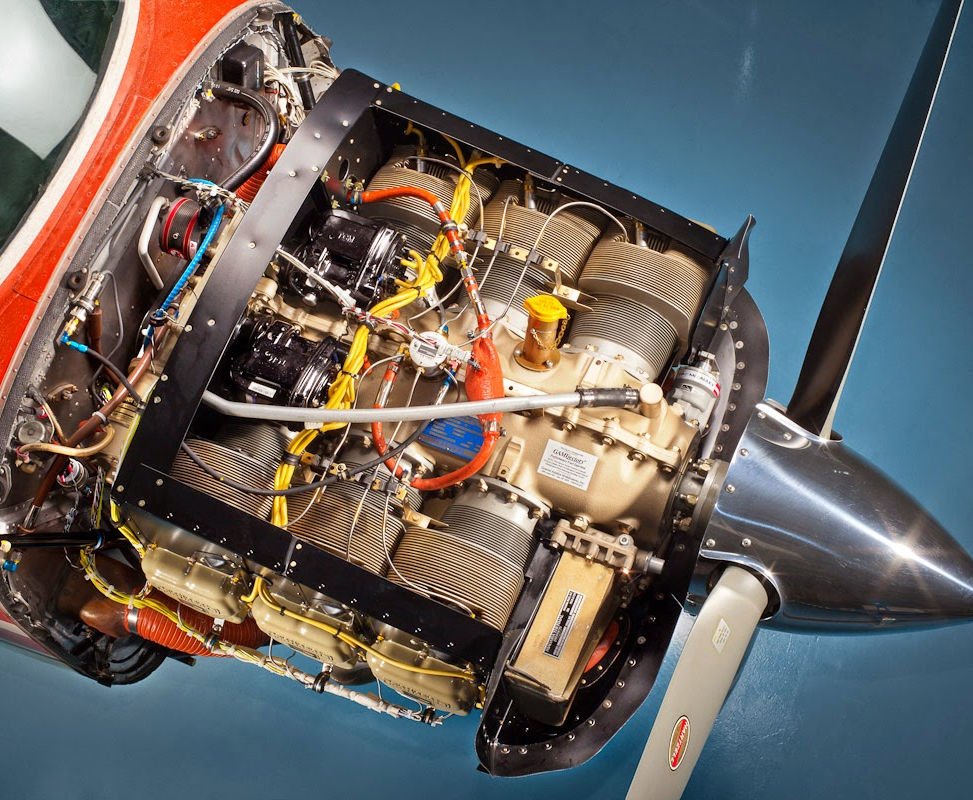

Aircraft Technical Knowledge and Principles of Flight (Aeroplane)

Private Pilot Licence (PPL)

Commercial Pilot Licence (CPL)

175 Questions

175 Questions

Air Law (Aeroplane and Helicopter)

Private Pilot Licence (PPL)

66 Questions

66 Questions

Human Factors

Private Pilot Licence (PPL)

Frequently Asked Questions

To access our mock exams, first, you need to register as a user for free on our website. Sign Up Here. After completing registration, please confirm your registration through your email (check your Junk folder).

Once registered, you can purchase a 6‑month subscription which grants full access to all our mock exams and offers discount compared to monthly payments.

With your subscription, whether it is monthly or six-monthly, you have unlimited access to all our mock exams.

Each subject offers different mock exam versions. You can retake each exam as many times as necessary, with no restrictions on the number of attempts.

Each subject comes with different mock exam versions. Every exam features a completely different set of questions. So when you retake a mock exam, you'll be exposed to new questions, providing a broader scope for testing your knowledge.

No, our goal is to simulate the real exam experience, similar to what aviation students face with NZ ASPEQ. Therefore, it’s important to be fully prepared before starting your mock exam.

However, if you need to step away, you can always restart the exam from the beginning. With your subscription, you can retake any mock exam as many times as needed.

YES, there is a time limit for each mock exam. Our objective is to closely replicate the real exam experience that aviation students encounter with NZ ASPEQ exams. The time limits for our mock exams are aligned with the actual exam constraints.

As soon as you complete your mock exam, the system automatically grades it and displays your results. You’ll see which questions were answered incorrectly, along with both your answers and the correct ones.

Additionally, each question includes a relevant syllabus study reference to help you identify areas for improvement. (HERE IS THE LINK TO AC61-3) & (HERE IS THE LINK TO AC61-5)

We greatly appreciate your feedback, as it helps us improve our services. If you encounter any errors or need clarification on any aspect of the mock exams, please fill out this form.

Once submitted, one of our instructors will review your feedback and contact you if needed.

No, we only provide mock exams to test your knowledge. When you’re ready to book your real exam, please use the link below:

Aviation Calculators

FREE and reliable aviation calculators made for kiwi pilots. Use this page to help you solve many calculation-related problems.

Start Calculating HereFlight Computer

Free online flight computer simulator to enable pilots and aviation students to learn and practice.

Start Calculating HereNavigation Flight Log

Automatically calculate True Airspeed, Heading, Distance, Ground Speed, Estimated Elapsed Time, Leg Fuel, and Fuel Remaining.

Start Calculating Here